A Rigid Backbone of Conductive Polyaniline (PANI) – composites

Today’s world is commending global energy due to fossil fuel development and ecological pollution which is overthrown by the direct methanol fuel cell[DMFC]. Amongst the conducting polymers, polyaniline plays a major role in the direct methanol fuel cell. Polyaniline (PANI) composites have developed as promising materials for enhancing the performance and stability of DMFCs due to their unique combination of properties, including high electrical conductivity, electrochemical activity, and chemical stability.

Historical milestones polyaniline (PANI) composites

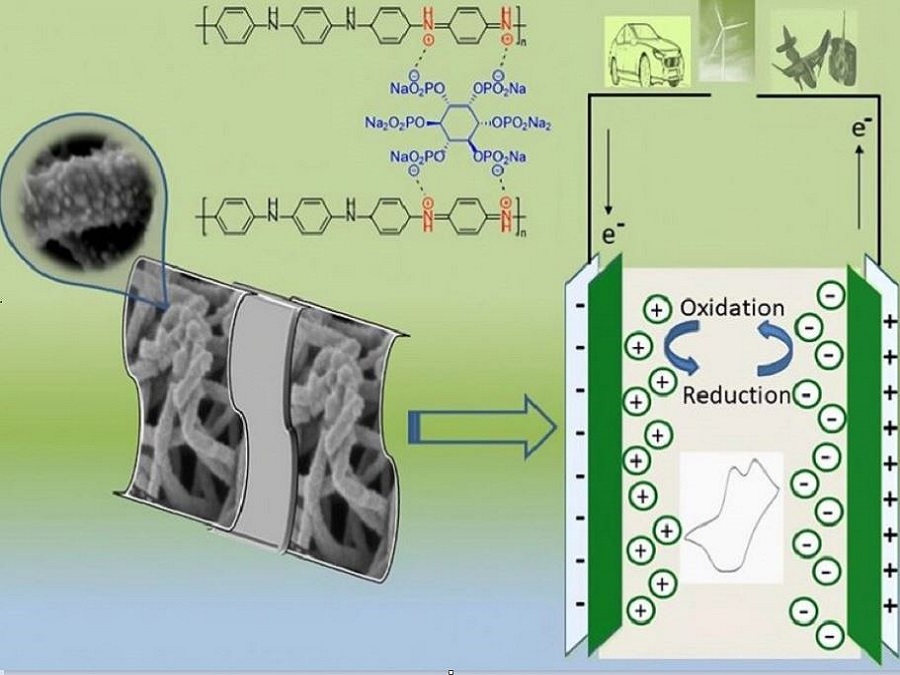

PANI composite membranes were developed to replace traditional proton exchange membranes (PEMs) in DMFCs. These membranes offered enhanced proton conductivity, methanol barrier properties, and mechanical strength, leading to improved fuel utilization efficiency and durability of DMFC systems.

Conducting polymer-based nanocomposites and nano blending technologies were extensively developed in various fields such as supercapacitors, solar cells, sensors, batteries, and different types of electronic device applications. And optoelectronic device applications. Despite their promising properties, the development of PANI-based nanocomposites faces challenges related to realizing the uniform dispersion of Nanofillers, directing the size and morphology of nanoparticles, and maintaining stability over time. Additionally, the scale-up of synthesis methods and the cost-effectiveness of production are areas that require further research and development. The key role of PANI nanocomposite in the electrochemical reaction of the composite electrode is because of the synergistic effect of the composite. Polyaniline-based nanocomposites offer exciting opportunities for advancing materials science and developing innovative technologies.

PANI-modified electrocatalyst for methanol oxidation in DMFC

The attainment of DMFC technology depends on changed factors such as membrane, anode, and cathode electrocatalyst. In this anode electrocatalyst exaggerated by the slow reaction, the kinetics can be overcome by capable new electrocatalysts. The conducting polymer-based electro catalyst newly plays a dynamic role in methanol electro-oxidation reaction (MOR). Particularly, PANI is a significant material for MOR.

Recent progress of PANI-based anode catalyst

1 Electrolytes: PANI composites can be integrated into the membrane component of DMFCs to improve proton conductivity, methanol barrier properties, and durability. PANI-based composite membranes, when combined with suitable proton-conducting materials (e.g., sulfonated polymers, inorganic nanoparticles), can enhance the proton transport efficiency while minimizing methanol crossover, leading to higher cell efficiency and stability.

2. Gas Diffusion Layers (GDLs): PANI composites can be used to modify the gas diffusion layers in DMFCs, improving water management, gas diffusion, and electron transfer kinetics. Incorporating PANI with carbon-based materials (e.g., carbon black, carbon nanotubes) or conductive polymers can enhance the conductivity and water repellency of GDLs, thereby reducing mass transport losses and improving cell performance.

3. Electrode Materials: PANI composites can also be utilized as electrode materials, particularly in the cathode of DMFCs, to enhance oxygen reduction reaction (ORR) kinetics. PANI-based cathode catalysts, when combined with suitable dopants and/or carbonaceous supports, can improve ORR activity, leading to higher cell voltage and power output.

4. Hybrid Membrane-Electrode Assemblies (MEAs): PANI composites can be incorporated into MEAs of DMFCs, integrating multiple functionalities such as improved proton conductivity, electrocatalytic activity, and mechanical strength. PANI-based hybrid MEAs can offer synergistic effects, leading to enhanced overall cell performance, durability, and cost-effectiveness.

Significant Potential for Overcoming Key Limitations

- Enhanced Electrocatalytic Activity: The electrochemical activity of the anode can be significantly improved. This leads to faster kinetics of methanol oxidation, enabling higher power output and efficiency of the DMFC.

- Improved Durability and Stability: PANI composites can enhance the durability and stability of DMFC components. This results in longer operating lifetimes and reduced maintenance requirements for DMFC systems.

- Reduced Methanol Crossover: The methanol permeates through the membrane from the anode to the cathode, is a major challenge in DMFCs as it reduces cell efficiency and can lead to fuel wastage. This improves the overall fuel utilization efficiency of DMFCs.

- Proton Conductivity Enhancement: PANI composites can also improve the proton conductivity of the electrolyte membrane in DMFCs to reduce internal resistance and improve the performance of DMFCs, particularly at high current densities. s

- Versatility and Tailor ability: PANI composites offer versatility and tailor ability in terms of their composition, structure, and properties. As a result, PANI composites can be customized to address the unique challenges associated with DMFC technology.

Future Specific applications of PANI composites in DMFCs

The integration of polyaniline (PANI) composites in direct methanol fuel cells (DMFCs) offers numerous potential applications across various sectors due to the improved performance and efficiency they can provide. For automotive applications, particularly in hybrid vehicles and range extenders, reducing reliance on conventional fossil fuels and lowering greenhouse gas emissions. Backup power systems operate in diverse environmental conditions making them reliable alternatives to conventional backup generators and batteries. Remote Monitoring and sensing is the ability to provide continuous and autonomous power to enable the deployment of sensor networks in remote or inaccessible locations, facilitating real-time data collection and analysis

The PANI composites can be tailored to address key limitations of DMFCs, including catalytic activity, proton conductivity, methanol crossover, and membrane durability. By optimizing the composition, structure, and processing techniques of PANI composites, researchers can enhance their electrochemical performance, reduce production costs, and enable scalable manufacturing processes for commercialization.

Techniques such as template-assisted synthesis, electrospinning, and chemical vapor deposition are being employed to fabricate PANI nanofibers, nanoparticles, or nanocomposites with enhanced electrochemical properties. Overall, PANI composite-based DMFCs offer a to improve its surface area, conductivity, and catalytic activity to clean, efficient, and sustainable energy solution with the potential to significantly reduce dependence on fossil fuels.

Source